GET NEW LOWER PRICING ON BULK INKS

18L WHITE INK CONTAINERS as low as RM0.56/cc

Save ink, save time and now save more money with new bulk ink pricing for your GTXpro B direct to garment printer. Engineered specifically for high-volume print shops that run multiple shifts, these large ink containers work ideally with Brother’s intelligent ink system to keep ink in a constant state of motion, so you get less waste and more uptime.

PRINT UP TO 42 DARK GARMENTS PER HOUR

(11″ x 11″ design at 1200 x 1200 dpi in CMYK+White in High Speed Print Mode)

PRINT UP TO 57 LIGHT GARMENTS PER HOUR

(11″ x 11″ design at 1200 x 1200 dpi in Standard CMYK Only Mode)

LESS IS MORE!

LESS IS PRO!

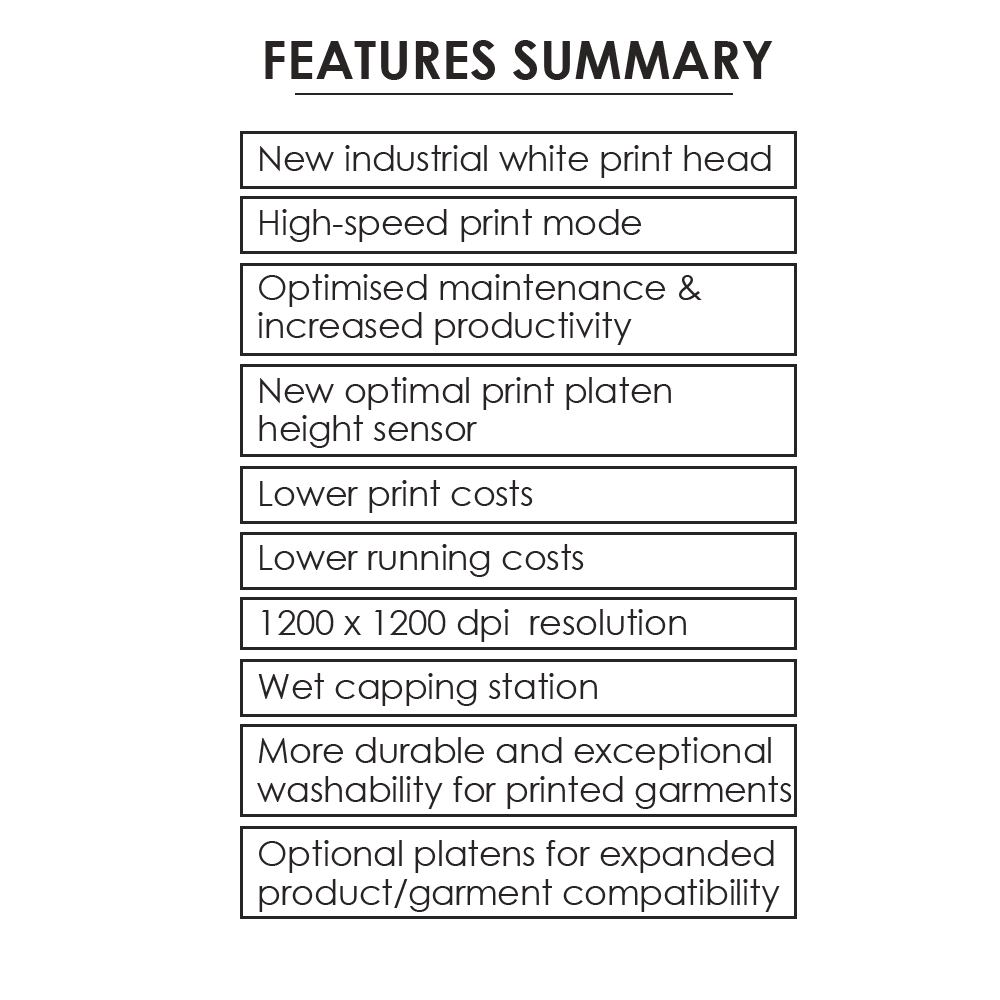

INTERNAL CIRCULATION & FAST MODE

New industrial white print head design allows for internal ink circulation inside the print head as well as throughout the machine, greatly reducing white ink wastage. A new ‘fast mode’ may now be enabled on your GTX Pro Bulk, cutting print times by 10% whilst maintaining 1200dpi print quality.

LESS WAITING & MORE PRINTING

Thanks to the new industrial print head design, further automation of maintenance procedures means no more need for morning preparation. The new cap design leads to a considerably shorter purging time and the larger color sub-tanks are now refilled during the printing process, all resulting in more time spent printing.

NEW MAINTENANCE

UNIT

The new re-designed maintenance unit allows for the removal of unecessary cleaning procedures. It simplifies the replacement of expendable parts by making them easier to access by the operator. Using smaller flushing foams reduces the ecological footprint of manufacturing Brother, making this a great eco-friendly machine.

CERTIFIED INKS & ECO FRIENDLY

The inks are manufactured according to Brother’s exclusive formulation to provide the best possible results. These DTG inks are amongst the first to not only carry the Oeko-Tex® Certification, but also to be GOTS APPROVED and CPSIA compliant* to help ensure they are safe for printing and environmentally responsible.

Graphic Lab

System Convenience

Flexibility

Eco Friendly Inks

Good Quality

Good Washibility

TECHNICAL SPECIFICATION

Print Method

Direct inkjet garment printer

Number of Ink-Heads

2 print heads / 8 ink channels

Machine Size

1780mm x 1300mm x 1210mm

Print Resolution

1200 dpi x 1200 dpi

Ink Type

Water-based pigment ink

Machine Weight

appox. 165kg including platen

Data output

Printer driver (USB, File output)

Ink-Head Type

On demand piezo head

Power supply

AC 110V-240V, 50/60Hz +- 1HZ

Display resolution

XGA(1024×768) (minimum recommendation)

Platen Sizes

Max Print Size is 40,6cm x 53,3cm / 16” x 21”

Included Platen Size

35,6cm x 40,6cm / 14” x 16”

OS

macOS 10.14 Mojave, macOS 10.15 Catalina Windows 8.1 (64bit), Windows 10 (64bit)

Power consumption

0.8A(average) (Reference: 0.4A – during circulation)

Print Mode

Single or double for CMYK. Underbase and highlight for white

Driver operating conditions

2GHz CPU (minimum recommendation) 4GB RAM (minimum recommendation)

Recommended Applications

Adobe® Photoshop CS6/CC, Adobe ® Illustrator CS6/CC, CorelDRAW ® 2018/2019 (Windows)

Environment

Standby Conditions: 10°C-35°C, 20%-85% Operating onditions: 18°C-30°C, 35%-85%

Pre-treatment

Before printing, apply pre-treatment using either a manual or automatic device and then dry garment using a heat-press, being sure to follow all manufacturer’s instructions. Pre-treatment is necessary for white ink.

Ink cure

Heat press machine can be used at 356°F (180°C) and 35 seconds duration. For higher volume production, a conveyor oven is recommended to be used at 320° (160°) for three and a half minutes. Time and temperature may vary depending on which manufacturer’s dryer is used.

Interface

USB2.0, LAN(10BASE-T, 100BASE-TX, 1000BASE-T), USB Flash Memory (Under 32GB, FAT32 format)